Supply chain disruptions may have caused up to $4 trillion in lost revenues in 2020 alone. The Intelligent Industrial Web holds immense potential to offset that and build resilient, futuristic chains.

Fostering Trust, Resilience & Transparency in Global Supply Chains.

Enabling Future of Trade & Commerce

If the pandemic has taught us anything, trust in supply or value chain is an underrated yet significantly impactful trait. The world has faced days of extreme turmoil due to disrupted supply chains. Our findings show that there has been a major shift in global supply chain strategy as redundancy, transparency, and resilience are deemed more important than speed and efficiency. At least 54% of senior executives surveyed say organizations must make significant changes to manage supply chain disruptions in the next five years effectively.

Intelligent Industrial Web (IIW) can significantly address the issues of the global supply chain. Supply chain data is not always visible, available or trusted. A lot of supply chains are predominantly orthodox and devoid of any smart technologies. IIW helps supply chain endpoints share trusted data, guarantee product authenticity, encourage responsible sourcing and increase overall transparency. Cosdec Alpha helps supply chain decision-makers use technology to handle the disruptions of today and build resiliency for the future while minimizing disputes.

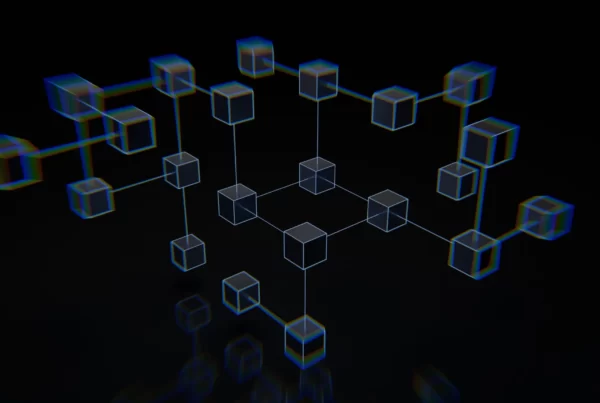

Streamlined Management & Trust

The Intelligent Industrial Web (IIW) can help speed up and streamline the management of Supply Chain nodes and endpoints for greater trust. Faster 3rd party onboarding, transparent records, automated actions & triggers, and easy settlement are all based on the Encrypted Nucleus Chain.

Real-time, immutable insights powered by the IIW can boost the output of continuous monitoring and improvement efforts. This constructs a supply chain that is truly fact-based and free of tampering. Immutable insights also mean long-term sustainability.

Higher Resilience

Automations give near real-time visibility into operations, and the ability to act preemptively in case of potential disruptions. This makes the supply chain more resilient with preemptive risk detection and mitigation.

Increased Transparency

Supply chain networks can be confined by one-up/down visibility. The Intelligent Industrial Web (IIW) can provide a shared, single version of the truth given its foundations on distributed ledger & relevant systems.

Bringing Industrial Intelligence to Supply Chain

Enabling faster, secure and streamlined operations at the the start of the chain.

Purchasing can be an increasingly complex process with various stakeholders and processes that are possibly beyond the control of a single source. However, all processes and stakeholders typically coincide at the buying end. There are several benefits to using IIW in purchasing, including Increased efficiency, Improved accuracy, Greater control, Better supplier relationships and much more.

The Intelligent Industrial Web (IIW) in purchasing refers to using emerging technology to streamline and optimize purchasing goods and services. This can involve using systems that allow for the creation and approval of purchase orders, the tracking of inventory levels, and the management of vendor relationships.

Developing higher efficiency & predictability in storage and movement of goods.

Warehousing & Inventory Management can get increasingly complex as the organization grows. The growing complexity also means a growing need for efficiency and productivity. A minor loss of effectiveness can translate to millions in financial losses.

The use of the Intelligent Industrial Web (IIW) in warehousing can help organizations to optimize their operations, improve efficiency, reduce costs, and enhance the quality and safety of their products and services.

Industrial intelligence can help to optimize inventory levels by providing real-time visibility into stock levels and demand patterns. It improves the accuracy and efficiency of order fulfilment by providing real-time visibility into warehouse operations and identifying bottlenecks in the process. It can help to identify and track quality issues, helping organizations to improve the quality of their products and services. Additionally, IIW can help to optimize the use of warehouse assets, such as conveyor belts and forklifts as well as help to identify and track safety and compliance issues.

Capturing untapped information and delivering insight-driven controls.

The Internet of Things (IoT) can be used in supply chain management to improve efficiency, accuracy, and speed by providing real-time data about the movement and condition of goods as they are transported and stored. The use of IoT in the supply chain can help companies to improve their operations and better meet the needs of their customers.

One way is that the use of sensors and other IoT devices can be attached to packages or containers to provide real-time tracking information.

This information can be used to optimize routes, reduce losses due to theft or damage, and improve overall visibility into the supply chain powered by the Intelligent Industrial Web (IIW).

The use of smart logistics systems can use real-time data from sensors and other IoT devices to optimize the movement of goods and reduce waste. For example, smart logistics systems can use real-time data about traffic and weather conditions to select the most efficient routes for delivery or use data about demand patterns to adjust production and distribution schedules in real time.

Fulfilling maintenance needs proactively while handling faults efficiently.

Predictive maintenance is a maintenance strategy that uses data and analytics to predict when equipment is likely to fail and to schedule maintenance and repairs in advance in order to minimize disruptions and downtime. Predictive maintenance can be used in a variety of industries, including manufacturing, transportation, and logistics, as well as in supply chain management.

In the context of supply chain management, predictive maintenance can be coupled with the Intelligent Industrial Web (IIW) and used to optimize the maintenance and repair of equipment and vehicles used in the transportation and storage of goods. By using data from sensors and other IoT devices to monitor the performance and condition of equipment, companies can identify potential issues before they occur and schedule maintenance and repairs accordingly.

This can help to reduce the risk of equipment failures, which can disrupt the supply chain and lead to delays and other problems. Predictive maintenance can also be used to optimize the use of equipment and vehicles, by identifying opportunities to improve efficiency and reduce waste. For example, by analyzing data on fuel consumption, companies can identify opportunities to optimize routes and reduce fuel consumption, or by analyzing data on maintenance and repair costs, companies can identify opportunities to extend the lifespan of equipment and reduce costs.

Overall, the use of IIW in supply chain management can help companies to improve the efficiency and reliability of their supply chain and better customer satisfaction.

Building efficient and automated manufacturing systems with greater reliability.

Manufacturing digitization refers to the use of digital technologies and the Intelligent Industrial Web (IIW) to improve and optimize manufacturing processes. This includes the use of digital tools and IIW systems to design, produce, and distribute products, as well as the use of data and analytics to improve decision-making and optimize operations.

The goal of manufacturing digitization is to improve efficiency, reduce costs, and increase the competitiveness of manufacturing operations.

There are a number of ways in which manufacturing can be digitized. The use of computer software to design and model products and production processes. The use of computer software and machine tools to automate the production of products. The use of robots and other automated systems to improve the efficiency and accuracy of manufacturing processes. The use of sensors and other connected devices to monitor and optimize manufacturing processes in real time. And, the use of data and analytics to improve decision-making and optimize manufacturing processes.

Setting new standards for efficiency and effectiveness of movement and storage of good.

In the context of logistics, the Intelligent Industrial Web (IIW) can be used to improve the efficiency and effectiveness of the movement and storage of goods, as well as to optimize supply chain operations. Not only does it help in meeting consumer & market demands more effectively but also helps in saving costs and maximizing financial efficiency.

Sensors and other IoT devices are used to track the movement and condition of goods in real-time, and to optimize routes and schedules accordingly. Data and analytics can be used to predict when equipment is likely to fail and to schedule maintenance and repairs in advance in order to minimize disruptions and downtime. IIW can predict future demand for goods, and adjust production and distribution schedules accordingly. It can also optimize inventory levels and reduce waste. Ultimately, IIW can optimize the flow of goods through the supply chain and improve efficiency.

Transforming supply chains to be future-ready, resilient and efficient.

The Intelligent Industrial Web (IIW) has the potential to transform supply chain operations by improving efficiency, accuracy, and speed, and by enabling new capabilities and business models. The use of futuristic technology in the supply chain has helped Cosdec Alpha’s clients to improve their operations and better meet the needs of an increasingly complex economic landscape. There are a number of ways in which the IIW can be used to transform supply chain operations.

How we approach a full transformation entirely depends on the merits of the organization and the structure of the supply chain. It is seen that applying the Intelligent Industrial Web (IIW) in this context has improved outcomes by as much as 250%.

Costs have been reduced, lead times and TAT metrics have been reduced, profits have been maximized and overall staff productivity has surged as a result of the application of futuristic technologies through the IIW.

IIW x Advanced Supply Chain Insights

Why Must Corporations Undergo A Comprehensive Web 3.0 Transformation?

Our Approach

Bringing The Future To You…

The Intelligent Industrial Web (IIW) can span across a large playing field with multivariate opportunities for all. We approach these technologies on a need-first basis with a focus on reducing costs while boasting deeper consumer relationships and higher enterprise value. At Cosdec Alpha, we have a structured, research-backed approach from understanding the needs of the client to delivering ultimate value. The commitment is simple as always – leverage the power of IIW to shape your evolution going into the future.

Getting Started

We would love to build an advanced, future-ready Supply Chain with you! Tell us your needs & aspirations and let’s see where that takes us.

Ready to Transform?